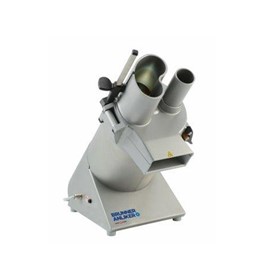

RG-400i-3PH is Halldes largest and most effective Vegetable Preparation Machine that prepares very large volumes, up to 3,000 portions/day or 2.4 tons/hour. The cutting tool range is broad; cuts, dices, shreds, cuts julienne, crimping slices and cuts French fries in a wide range of dimensions. There is a broad range of feed attachments and accessories, enabling adaption to many different needs.

RG-400i is a floor model, with a compact shape, of high quality, manufactured in stainless steel, ergonomic and very easy to clean. The cutting tools, feeders and accessories can be cleaned in the dishwasher. RG-400i fulfils all of the requirements that are placed on a professional Vegetable Preparation Machine independent of which environment it is used in: restaurants, large sized kitchens, industrial environments, catering or as a part of a production system.

RG-400i-3PH MANUAL PUSH FEEDER WITH 4 TUBE FEEDER SETUP (THREE PHASE)

- Food manufacturing capacity vegetable preparation. Make more than 50 different cuts. Slice, crimp, julienne, shred/grate, dice & potato chip.

- Processes up to 3,000 portions/day, 40 kg/minute or up to 2.4 tons/hour.

- Price includes Machine Base (HA37062) and Manual Push Feed Attachments (comprising HA37063 Type A Feed Cylinder, HA37060 Manual Push Feeder & HA37105 4 tube feeder)

- Full moon feed head

- Stainless steel housing & feed head

- Large 215 mm diameter cutting tools

- Over 44 different discs available to suit all requirements (see cutting tools list)

- Three phase only 1500W, other voltage/cycles on application

- Cutting tools and trolleys not included in the machine price

- 4 tube feeder allows slicing of long vegetables eg carrots, cut transversely

Overview:

Perfect cutting results

RG-400i-3PH has a broad range of cutting tools that cut, dice, shred, cuts julienne, crimping slices and cuts French fries in a wide range of dimensions and prepares both hard and soft products. The cutting tools large diameter of 215 mm in combination with the spacious feed cylinders means that RG-400i-3PH can handle very high volumes at each fill. The rotation speed of the cutting tool is optimised to make even cuts as effectively as possible. The knives are ground according to purpose in order to retain their sharpness for a long time and are available as spare parts when it is time to replace them. The machine has two speeds 200 rotations/minute and 400 rotations/minute.

Best hygiene

All removable parts are manufactured in stainless steel and can therefore be washed in a dishwasher. The machine base, also in stainless steel, has smooth surfaces, rounded edges and lacks unnecessary recesses into which food can penetrate and get stuck. When the stainless removable tray is used, cleaning is facilitated even more because it can easily be taken out of the knife housing and cleaned in the dishwasher. In this way the machine base itself is kept free from the products that are being prepared. Thanks to the distance of 150 mm between the machine and the floor it is also easy to clean the floor under the machine. With help of the sturdy handle and the robust wheels on two of the machines legs it is easy to move. RG-400i-3PH is manufactured solely of food approved material.

A model safety system

The RG-400i features two safety systems that prevent the machine from running when the cutting tool is unprotected. In order for the machine to start, the feed cylinder must be correctly mounted and the feeder must be in the right position and covering the cutting tool.

Manual Feeder

Can prepare all types of products, both large and small. The Ergo-loop design gives a lever effect which also reduces the need for manual force when preparing large and hard products such as root vegetables, cabbage and cheese. For fast and safe preparation, the machine stops when the feeder is moved to the side and starts automatically when it covers the feeder cylinders opening.

4-Tube Insert

In order to easily be able to cut long and narrow products standing, and round products in a special direction, the 4-Tube Insert is used. The feeder has four tubes with the following diameters: 73 mm (two tubes), 60 mm and 35 mm. The tubes give good support for products in a range of different sizes, such as cucumber and leeks. In the tube it is also simple to “bunch together herbs and parsley, etc. When the 4-Tube Insert is used the machine runs continuously because the rotating cutting tool is covered by the feeder at all times.

Read less...

To contact Cater Inc about Hallde Manual Feed Vegetable Cutter RG-400i use Get a quote.