- Suppliers

- New to HospitalityHub? Book a Demo

- Advertise with us

- Login

- Email Marketing

- Buyers

- Get Quotes

- Articles & Ideas

- Login

- Subscribe to newsletter

- My Details

- Get Quotes

- Bakery & Dough Processing Equipment

- Bar Equipment & Barware

- Bathroom Fixtures & Accessories

- Chocolate Making Machinery

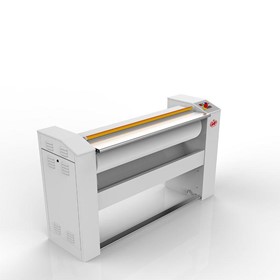

- Cleaning, Laundry & Housekeeping

- Commercial Coffee Equipment

- Commercial Cooktops

- Commercial Fridges & Freezers

- Commercial Fryers

- Commercial Kitchen Equipment

- Commercial Ovens

- Dish, Utensil & Glass Washing

- Entertainment & Outdoor

- Food Packaging & Ingredients

- Food Preparation Equipment

- Furniture & Fixtures

- Industrial Fans & Ventilation

- Material Handling Equipment

- Pizza & Pasta Making Equipment

- Point of Sale, AV & Technology

- Get Quotes

- Bakery & Dough Processing Equipment

- Bar Equipment & Barware

- Bathroom Fixtures & Accessories

- Chocolate Making Machinery

- Cleaning, Laundry & Housekeeping

- Commercial Coffee Equipment

- Commercial Cooktops

- Commercial Fridges & Freezers

- Commercial Fryers

- Commercial Kitchen Equipment

- Commercial Ovens

- Dish, Utensil & Glass Washing

- Entertainment & Outdoor

- Food Packaging & Ingredients

- Food Preparation Equipment

- Furniture & Fixtures

- Industrial Fans & Ventilation

- Material Handling Equipment

- Pizza & Pasta Making Equipment

- Point of Sale, AV & Technology

Trusted by 220,000 Australian hospitality buyers

Buyers

- Discover products & solutions

- Login

- Subscribe To Newsletter

- Browse All Products

- Read Articles

Suppliers

Advertise

- Promote your products & solutions

- New to HospitalityHub? Book a Demo

- Login / Forgot Password

- Advertise Your Products

- Success Stories

- Email Marketing

Trusted by 220,000 Australian hospitality buyers

-280x280-state_7.jpg)