Accurate food labelling is one of the most menial yet extremely crucial tasks for any quick-service restaurant (QSR). If done properly, stores can ensure that each item in the kitchen is accounted for and that stock is being rotated in a timely manner. On the other hand, improper labelling costs QSRs a lot of money because of food waste and inefficient stock management, not to mention risking noncompliance in safety and hygiene protocols.

Food labelling proves to be one of the biggest pain points for QSRs, including Vietnamese food chain Roll’d, which recently opened its 100th store nationally. As a massive multi-site restaurant brand, Roll’d struggled with the inconsistency of a “prehistoric” food labelling system they used to have.

“We relied on team members knowing the shelf life of products or checking these on a chart, calculating the expiry dates and transferring these onto the product. This system leaves the team open to error and products potentially being used past the shelf life,” says Stefan Grbovac, Franchise Business Coach at Roll’d.

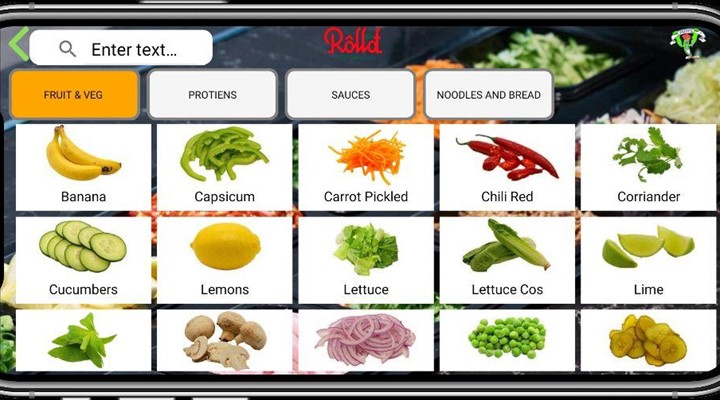

To address this inefficiency, Roll’d partnered with PREPsafe, the market leader in automated labelling systems for restaurant kitchens. “We implemented PREPsafe to have a one-shoe fits-all approach to labelling, to help ease the pressures around store operating and EHO visits. Ultimately, we are looking to grow exponentially and push towards HACCP certification, and this system puts us on that path,” says Jake Squires, Franchise Business Coach at Roll’d.

For Roll’d, PREPsafe is a consistent labelling system providing all the details required to manage stock rotation accurately. Its simplicity also allows the system to be rolled out with minimum effort.

Roll'd franchise business coaches Stefan Grbovac and Jake Squires.

“The system was really easy to set up. We can add our ingredients and create custom templates for different systems in-store. PREPsafe founder George Walton has been fantastic in helping make the process streamlined and answering all the questions we as a company had,” notes Squires.

Grbovac agrees and says rolling out PREPsafe was extremely simple. “The set-up can be done remotely with a simple step-by-step guide and George is on hand for any technical support. Once tested in-store and the decision made, the national rollout was completed extremely quickly,” he adds.

PREPsafe’s new Preppy App helps brands implement a labelling system that is a lot more efficient and cost-effective than any other manual method. According to Grbovac, PREPsafe allows their teams to be able to easily identify out of date products which are then discarded ensuring customers receive the best quality meals.

“In addition, it can highlight inefficiencies in wastage control and help the managers adjust prep levels. PREPsafe also makes food safety training for our new team members easier as all information required for FIFO and product dating is on a clear label.”

With its revolutionary yet easy-to-use labelling system, PREPsafe is well-received by Roll’d franchisees and store employees. Instead of spending so much time manually writing labels, staff can now be deployed to take on more important tasks especially when the store gets busy.

“PREPsafe is a fantastic value add to our stores. It saves time for the staff when they are prepping products, allows the teams to check that all products are within shelf life faster and speeds up audits by field staff and EHO inspectors when checking FIFO,” says Grbovac.

Ultimately, PREPsafe has made food hygiene a lot simpler for Roll’d. Its efficiencies allowed the chain to focus more on other operational areas to ensure that customers receive the best service and meals.

“PREPsafe has provided us with a simple and effective solution to our compliance and labelling. The teams have embraced the change and have been asking us, ‘why didn’t we do this sooner?’” concludes Squires.